Business

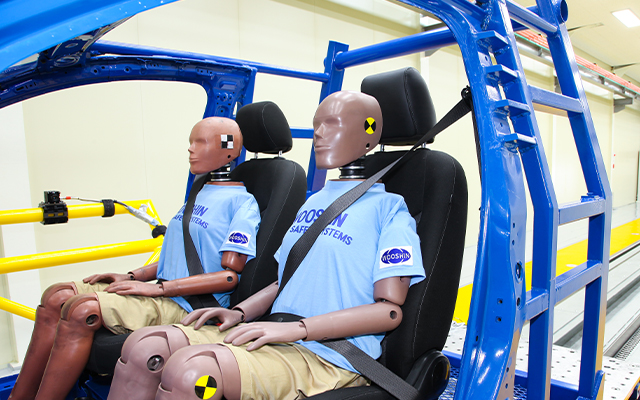

SAFETY BELT SYSTEMS

SAFETY businessSeat belts are a representative automobile safety component that is directly related to the safety of passengers,

and global customers are demanding advanced technology and flawless quality.

Wooshin meets 100% of our customers' technical and cost needs with our proprietary technology product line.

Our main products include Retractor, Retractor Pretensioner, Buckle, lap Pretensioner, Height adjuster & Guide loop and

we’ve been developing and producing them.

and global customers are demanding advanced technology and flawless quality.

Wooshin meets 100% of our customers' technical and cost needs with our proprietary technology product line.

Our main products include Retractor, Retractor Pretensioner, Buckle, lap Pretensioner, Height adjuster & Guide loop and

we’ve been developing and producing them.

-

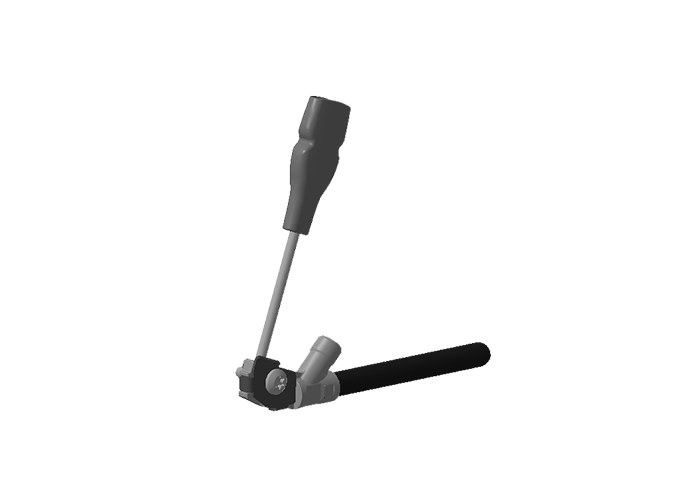

KR21P

CLL & ALL -

R30P2

CLL & ALL -

R30P2 AMR

(MSB)

-

Buckle

-

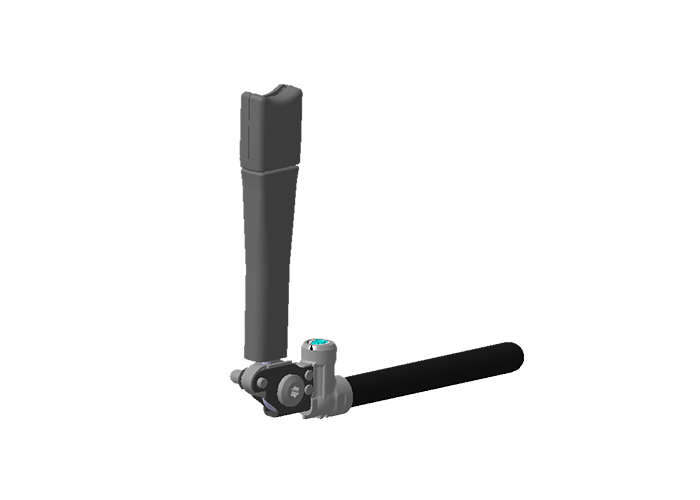

Lap PT

-

WBS

(Wireless Buckle Switch)

-

KR20

ELR -

KR21P

CLS -

R30P2

PLL -

HMS

(High angle

Moving Sensor)

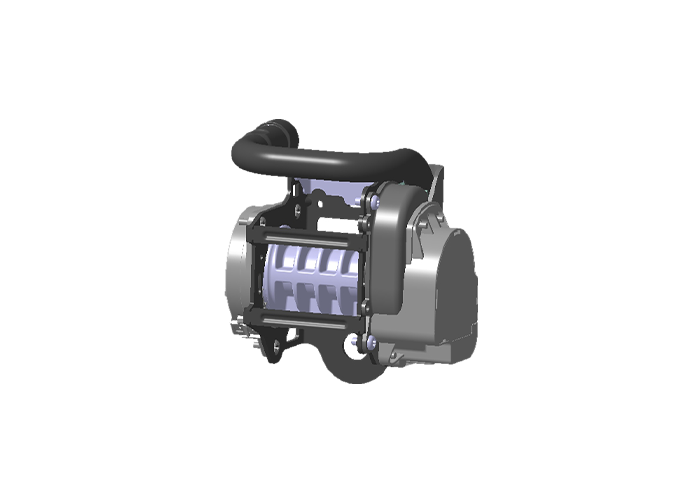

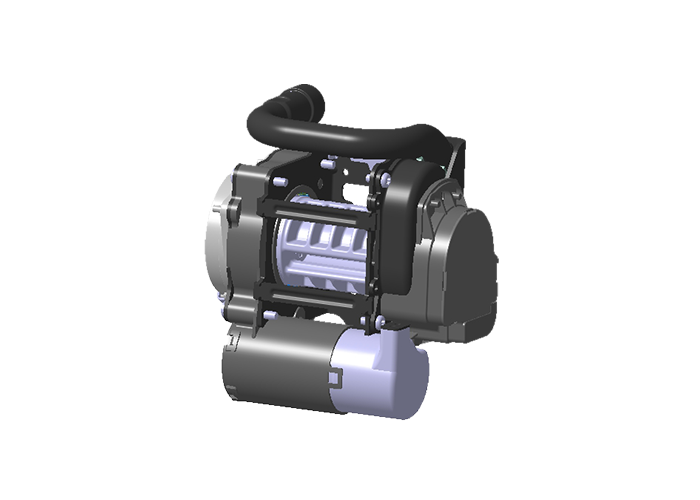

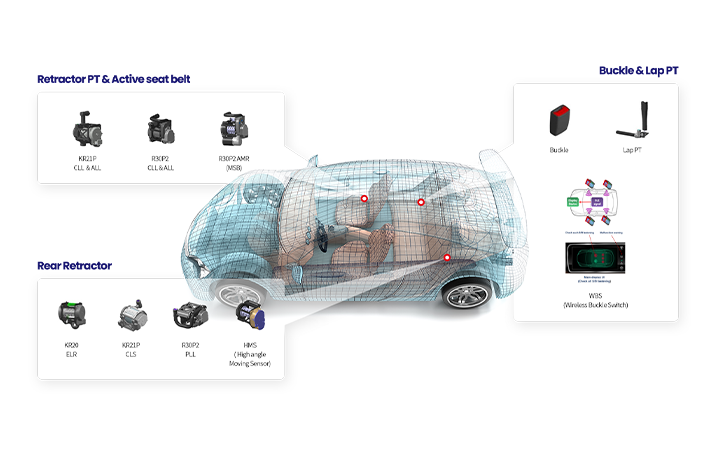

Retractor PT & Active seat belt

-

KR21P

CLL & ALL -

R30P2

CLL & ALL -

R30P2 AMR

(MSB)

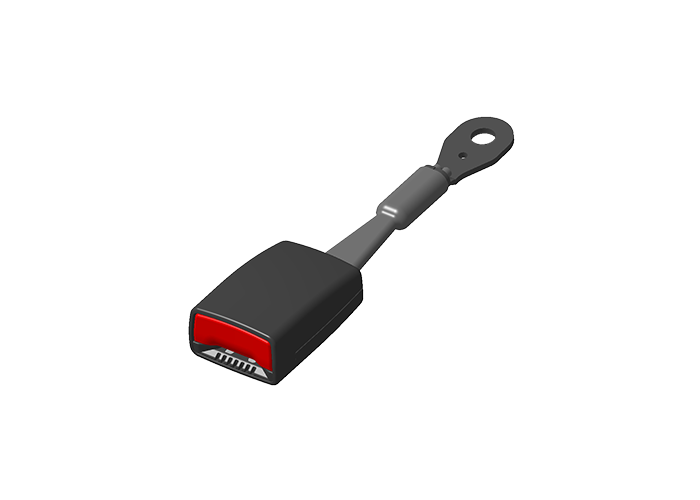

Buckle & Lap PT

-

Buckle

-

Lap PT

-

WBS

(Wireless Buckle Switch)

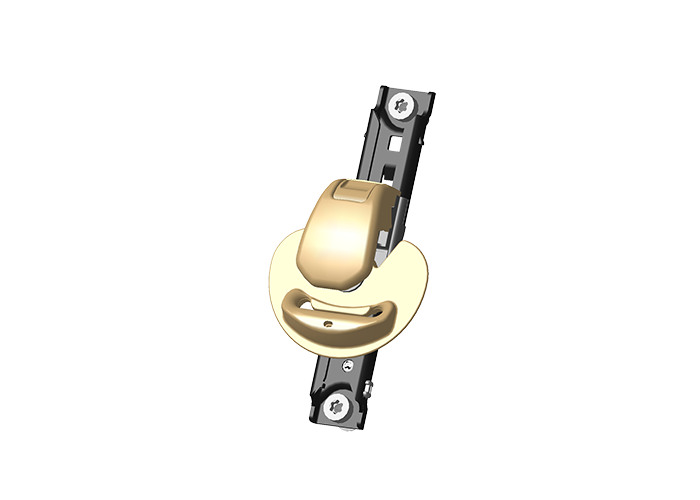

Rear Retractor

-

KR20

ELR -

KR21P

CLS -

R30P2

PLL -

HMS

(High angle

Moving Sensor)

Main products

Core Competitiveness

Development

Plan

Reflection of Lessons Learned and VOC

Design Evaluation based on DFMEA

DFSS/TRIZ method for robust design

Optimal Design considering Productivity

Design Evaluation based on DFMEA

DFSS/TRIZ method for robust design

Optimal Design considering Productivity

Component

Preparation

Reinforcement of Component Development Process

Secure Component Quality Reliability

Expand BIQS Activity to Tier II

Strengthen Incoming Inspection

Secure Component Quality Reliability

Expand BIQS Activity to Tier II

Strengthen Incoming Inspection

Assembly

Process

Process Improvement based on PFMEA (+Reverse PFMEA)

Manufacture Reliable Product through Automation

Continuous RPN Reduction Activities

Continuous BIQS Activity

Manufacture Reliable Product through Automation

Continuous RPN Reduction Activities

Continuous BIQS Activity

Reference