Business

INTERIOR

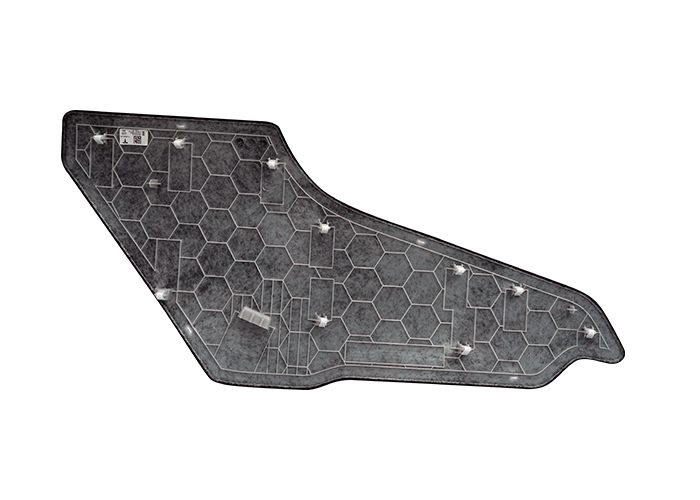

Automotive Interior ComponentsWooshin System’s technological strengths breathe life into every concept with

which we design and manufacture our interior trim components and parts.

which we design and manufacture our interior trim components and parts.

PRODUCTION PROCESS

Material input

Injection resin/subsidiary materials/fabric input

Resin drying

Drying injection resin (PP+TD20) 60˚C for 2 hours

Fabric integral molding

After inserting the fabric, the fabric is molded using a direct injection method (core-back technology applied)

Strain relief jig

Strain relief jig is used to minimize deformation during natural cooling after injection

Loading

Stored by specification on factory mobile truck

Cutting

Cut off unnecessary parts, leaving the wrapping area

Bond

Application and drying

Wrapping

Wrapping the bonded and dried product by pressing it on the back

Assembly of subsidiary materials

Assembly of subsidiary materials such as fasteners, bolts, SRS CAP, etc.

Inspection

Sealing/missing/appearance inspection

Barcode Reading

Product specification barcode and ALC code consistency check

Packaging and Shipping

Packing according to the packaging specification and reading the box label barcode

Main products

Current status of facilities

| Type | Tonnage | Quantity | Category |

|---|---|---|---|

| Injection | 1,300 TON | 2 | Hydraulic type |

| 850 TON | 6 | Hydraulic type | |

| 850 TON | 3 | Motorized toggle type Core Back / Double spout |

|

| 650 TON | 1 | Hydraulic type | |

| 450 TON | 1 | Hydraulic type | |

| 300 TON | 1 | Hydraulic type | |

| 220 TON | 3 | Hydraulic type | |

| 17 |